WE ARE YOUR SOLUTION

Crane with advanced automation features for a heat treatment plant enhances process accuracy, reduces cycle time and assures safety.

Crane with advanced automation features for a heat treatment plant enhances process accuracy, reduces cycle time and assures safety.

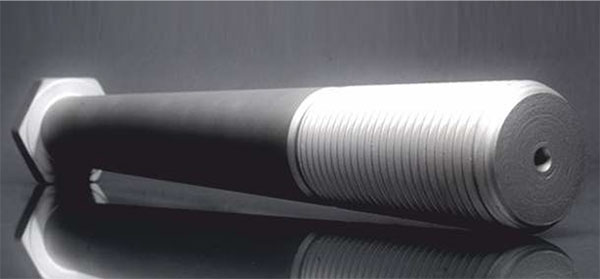

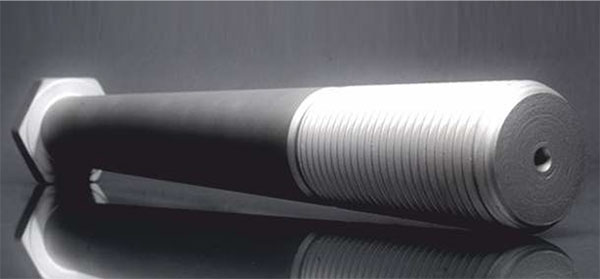

Randack specialises in manufacturing high tensile fasteners for diverse markets. In India, the company is promoted by Randack Spezialschrauben, Germany, a pioneer in the field of specialised fasteners. Randack’s product range includes bolts, nuts, machined parts and fasteners, which are mainly used by energy, aviation, construction, oil & gas, transportation and heavy engineering sectors.

Besides the usual low alloy steels, Randack uses a variety of high alloy steels, special steels and other materials to produce high quality tensile fasteners.

Fasteners play an important role in the safety of a structure, machinery or equipment and fasteners from Randack are known for their high reliability.

Heat treatment is an important process in fastener manufacturing which ultimately decides the quality and reliability of fasteners. Randack, Pune plant has an in-house Heat Treatment Facility with SCADA control and is qualified as per AMS 2750 standard.

During the heat treatment, heating temperature, time and the quench process vary depending on the fastener material and require meticulous control on process parameters. In a heat treatment process, first, the materials are heated to between 800°C and 900°C. The second step is the quenching process where the materials are soaked in water, oil or air to obtain certain material properties. The process reliability is governed by precise control on temperature as well as the soaking time.

Considering these aspects, Randack intended to automate the process of handling baskets of fasteners during quenching. An automated system would minimise the manual intervention that is risky considering the high temperature even in the surrounding areas of process tanks. Moreover, an automated system was required to strictly adhere to the quenching duration, which is about 40 to 60 seconds depending on the material.

The challenge was to configure a crane to achieve automation for long traverse, halting at precise locations, lowering the load and lifting it back from the soaking tank after the predetermined time duration.

This was a unique requirement where automation was to play a key role. Our design experts conducted an in-depth study of the entire work cycle and interacted with different stakeholders to understand their problems and expectations from a new system. The insight helped us to design a crane solution with the highest possible level of automation, which could lead to safe operations and improve process accuracy.

We have designed and installed a Double Girder Gantry Crane having 5t load capacity, 13m span and 7m height of lift with the following features:

The crane being operational in the above-normal temperature zone, special components are used which could withstand higher temperatures

Advanced level of automation helps in reducing manual intervention

Higher precision can be exercised on process duration

Reduction in the wastage that occurred earlier as a result of lack of precision control on process duration

Enhanced safety of operator and material

Reduced cycle time resulting in higher productivity. From earlier 55–60 seconds, the cycle time is reduced to 30–40 seconds.

Energy saving as the tank idling time is reduced as a result of faster cycle completion

Total number of crane: 1

| Type | SWL | Span | Height Of Lift |

|---|---|---|---|

| DG EOT | 5t | 13.00m | 7.00m |

Disclaimer

© Copyright 2020 | All the names and logos used here are the registered trademarks of respective companies. For private circulation only. Certain data mentioned here is based on assumptions and theoretical calculations, hence may not be accurate in practice and can’t be considered as a claim by the company.