Double girder gantry cranes contributing to infrastructure projects

WE ARE YOUR SOLUTION

Our contribution in building two of

India’s latest landmark infrastructure projects

About Gammon India Ltd.

Gammon, a leading infrastructure development player in India has often placed its trust in ElectroMech as its one-stop material handling solutions provider. ElectroMech has always contributed its best by getting involved with Gammon right from the initial project planning stages to help it achieve the smoothest possible project execution. ElectroMech cranes are relied upon for their precise engineering design as they demonstrate quality operations at various projects being executed by Gammon and other infrastructure companies in India and across the world.

Gammon executed two gigantic and unique infrastructure projects, one in Patna and the other in the nation’s capital, Delhi. Both these projects create a landmark in the respective cities through their distinctive design, apart from their functional role in enhancing the transportation network within the city. ElectroMech is proud to be associated with these projects.

A glimpse of the landmark projects

Signature Bridge, Delhi

Delhi Tourism & Transport Development Corporation Ltd. (DTTDC) has constructed the Signature Bridge in New Delhi which connects Wazirabad to the inner city via a bridge across the Yamuna river. The project involved the construction of a 0.675 km eight lane bridge, a water sports and recreational centre and a tourism park adjacent to Signature Bridge site. The aim of the project was to reduce the traffic on the existing Wazirabad Bridge as well as market the location as a tourist destination. The Signature Bridge has dramatically improved access between north and west Delhi. It has also become one of Delhi’s key attractions, encouraging domestic and international tourism to the capital city of India. Signature Bridge is an unsymmetrical cable-stayed bridge. The boomerang shaped pylon consists of two inclined columns, which are rigidly connected to the driving lanes and bend mid-way. The height of the steel tower is approximately 150m. The upper portion of the pylon anchors the back-stay cables as well as the main span cables, arranged in a harp like manner. Graphics on the bridge structure are featured for the 'first-time' in the world. The pattern chosen reflects Indian culture and at the same time symbolises a modern and progressive India. The tip of the pylon is created by a 30m high steel and glass structure, which is illuminated to create a landmark visible from afar at night.

ElectroMech is instrumental in the smooth execution of several landmark projects executed by Gammon across India. This includes underground drinking water projects, bridges, flyovers, metro rails and construction.

A glimpse of the landmark projects

Ganga Path Project, Patna

This is one of the prestigious projects commissioned by Bihar State Road Development Corporation (BSRDC). This project involves development of a 11.9 km long 4 lane elevated road corridor between AIIMS and Digha in Patna. The road provides much relief from the traffic congestion in the city, particularly on the narrow Ashok Rajpath as it connects the Loknayak Ganga Path at Digha end. This project is undertaken for the construction of 2 lane semi-elevated and 4 lane elevated highway over Patna canal as approach road of rail-cumroad project across the Ganga at Digha.

It has 2 km of 2 lane semi-elevated and 9.90 km of 4 lane elevated roads. This elevated road has major crossings at Bailey Road and Ashok Rajpath and offers connectivity with important places like Danapur railway station, Patliputra railway station and AIIMS. Besides, it also has connectivity with the Loknayak Ganga Path and one railway bridge at Khagaul (Patna-Delhi) line.

Gallery

The handling challenges at Gammon

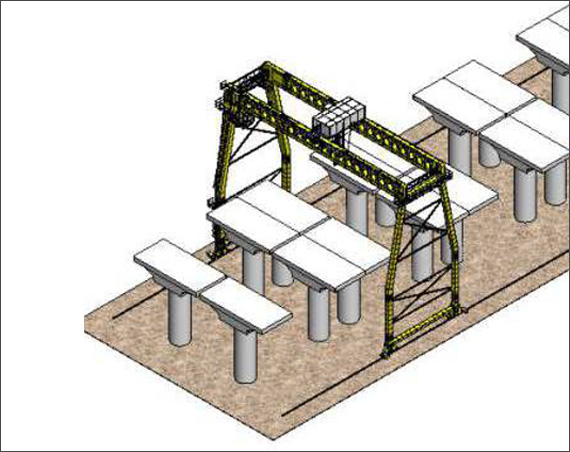

Gammon was appointed as the construction contractor for the Signature Bridge and Loknayak Ganga Path elevated road projects, which are being executed simultaneously. At both the projects precast segments were used to construct the bridges, hence heavy-duty gantry cranes were required for handling precast segments and girders. Being equally prestigious, critical and time-bound projects, Gammon was looking for a competent and reliable crane solution provider. Considering the precise solutions capability and reliable performance of ElectroMech cranes for various other challenging projects executed by Gammon, they selected ElectroMech as a partner for these prestigious projects too.

Challenging projects demand for a competent solutions provider and reliable equipment. For the massive precast segment handling requirements of Gammon, ElectroMech has always been the obvious choice.

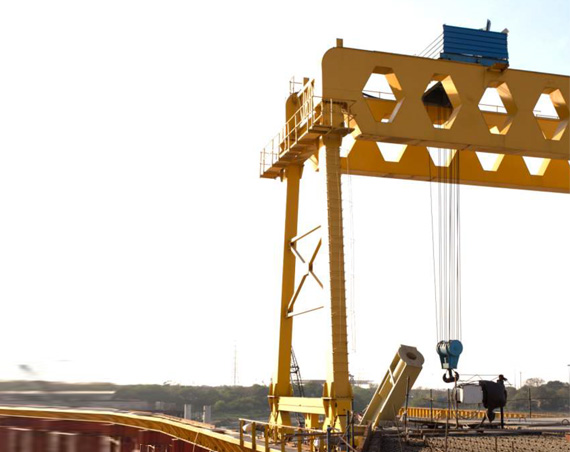

Solutions from ElectroMech for Signature Bridge, Delhi

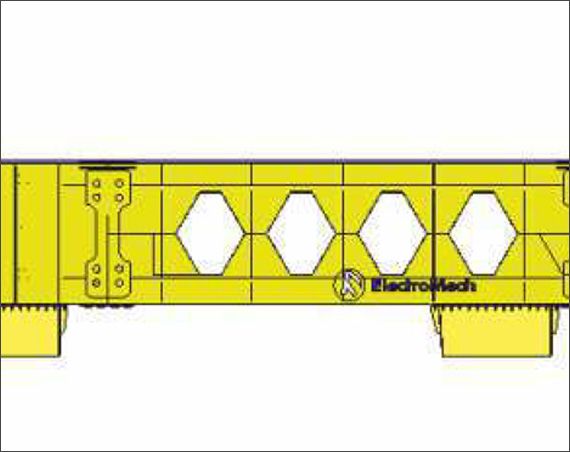

The material handling requirement for such infrastructure projects is always challenging considering the vastness of the project and the site conditions themselves. After thoroughly evaluating all the requirements individually, the ElectroMech team suggested a 60t castellated double girder gantry crane with 40m span and 12m height of lift for the Signature Bridge project in Delhi. Signature Bridge was a unique project, due to its unconventional type of crane installation and application. Here the crane was erected at a height on a support structure beside the bridge girders. As this project is executed over the banks of river Yamuna, Gammon had made such type of an arrangement in order to facilitate smooth and swift installation of precast segments. Gammon required equipment which ensured stability and precision while working on the heights. Keeping all this in mind ElectroMech R&D team came up with a castellated girder type design. This has proved to be an effective solution for Gammon. This design has enabled reduction in the overall structural weight of the crane ultimately lowering the wheel loads up to 30%, thus making it a lighter yet stable crane to execute operation at heights. The reduced surface area of the main girders enabled approximately 20% reduction of wind loads which in turn helped the crane to work swiftly and easily against the high wind pressure. Apart from this, the crane included one more feature of diesel generator set. This significantly helped Gammon to reduce the project cost by eliminating the use of electric cables which could have been a major cost concern while executing such a vast and long dimension project.

Solutions from ElectroMech for Ganga Path Bridge, Patna

For construction companies, it is the norm to write off the cost of their capital equipment such as cranes in a single project. This, of course, directly affects the profitability of the project. Conversely, being able to reuse their cranes for another project offers a huge advantage in terms of profitability, a scenario that several of ElectroMech’s construction clients have been able to benefit from. ElectroMech cranes have proved themselves to be rugged, reliable and long lasting. Several EPC companies use them over the years on a number of projects - one after the other. Admirably, ElectroMech has reconfigured and modified its cranes for several of our clients prior to shifting them to their new project site to ensure optimal performance and ensure economics. For this project too, this factor was taken into account at the design stage itself. Once the cranes have completed their duty at their respective projects, they can be easily used at other projects by changing their span or height of lift as required. In fact, at the Loknayak Ganga Path site, the site conditions necessitated different configurations of crane heights, a condition that could have warranted the use of different cranes depending on their location within the site. ElectroMech’s team of engineers came up with an ingenious solution that allowed Gammon to use the same crane to construct the complete flyover in two different configurations as well as facilitate easy modification to suit the requirement at future projects.

Complex projects always demand efficient and apt equipment to address varied handling needs, depending upon the nature of site complexities. This helps the end user to optimize capital investment, reduce project costs and assure swift executions. ElectroMech cranes are just ensuring this at Ganga Path and Signature bridge projects simultaneously.

The handling challenges at Gammon

Three different spans in a single crane

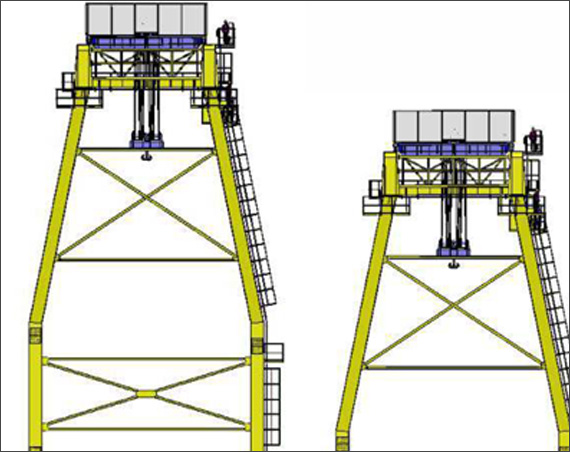

After careful consideration of the typical projects undertaken by Gammon, the cranes were designed to allow fixing the legs and cabin at any of three different locations. With this arrangement, the crane span can be adjusted to 19.4m or 28m or 33.5m for the Loknayak Ganga Path project crane. While in the Signature Bridge project crane, the span options available are 19.4m, 28m and 40m. This arrangement allows the crane to be configured to suit almost any future project that Gammon executes, in minimal time.

Flexibility to work at different heights

At the Loknayak Ganga Path site, Gammon had a limitation with the working height at one end of the bay due to a high tension electricity line. We offered a solution to this situation by designing height adjustable crane legs. The crane legs are designed to operate at two different height of lifts. Initially the legs are assembled for a lift height of 18m and later the leg extension sections can be added to assemble the crane for 25m lift height in order to carry out construction in the area post clearance of the electricity line.

Maximum coverage in spite of site constraints

Every project demands optimum solutions to suit the site requirements, which govern the design of any material handling equipment. At the Loknayak Ganga Path site, a canal on the side of the bridge site posed a constraint for the installation of the gantry crane. This meant that the crane legs would have to be very close to the edges of the bridge segments, leaving very little margin for error. The design was optimised for minimal hook approaches to ensure maximum coverage of the clear span between the gantry legs.

Challenges

- Cranes to withstand heavy wind pressure while working at heights

- Providing solutions that prove to be highly cost effective was a major concern

- Reliable performance in harsh working conditions and adverse climatic conditions

- Necessity of different configurations of crane heights to warrant different location requirements within the same site

- A canal on the side of the bridge site posed a constraint for the installation of the gantry crane

Solution

- Castellated girder design, resulting in reduction of structural weight making the crane lighter to be installed at the height and carry out operation swiftly

- Reduction in the surface area of the main girders enabled cranes to withstand the wind loads at the height and enhance stability

- Ingenious design which provides several span configurations in one single crane. This allows the crane to be configured to suit almost any future project requirements, with great cost-efficiency

- Flexibility to work at different heights, using the same crane in two different configurations to construct the complete flyover

- Optimised crane design for minimal hook approaches to ensure maximum coverage in order to overcome the space constraint on the site