Double girder gantry cranes for heavy lifting in the infrastructure industry!

WE ARE YOUR SOLUTION

Proven performance and reliability of

ElectroMech cranes in precast yards

across the world make us a preferred

solutions provider in this industry

About PIIPL

Precast India Infrastructures Pvt. Ltd. is a joint initiative between one of Pune’s most reputed civil contractors, Bhate Raje Construction Company Pvt. Ltd. and leading real estate developers, Panchshil Developers. PIIPL was founded in 2010 with a mammoth production facility in Wade Bolhai, on the outskirts of Pune. Spread over 63 acres, this state-of-the-art precast factory is one of the largest in India. Full scale production started here in 2012.

PIIPL undertakes high volume contracts for IT buildings, commercial complexes, industrial and residential buildings. They offer a one-stop ‘design and build’ solution and have successfully completed several projects with a cumulative built-up area close to 4 million sq.ft.

Leader in precast industry, PIIPL reaffirms its trust in ElectroMech

The handling challenges at PIIPL

For their new plant, PIIPL was looking for suitable solutions to meet various handling requirements in the plant. The applications included handling moulds and precast segments in the outdoor area and handling smaller moulds and precast columns inside the factory.

The essential criteria for selection were the performance and reliability of cranes, time-bound completion of the project and capability to offer swift and efficient service support. Excellent support on the previous projects corroborated PIIPL's trust in ElectroMech while expanding the production capacity.

How PIIPL benefited from ElectroMech solutions

- Lifting and stacking of heavy elements in a single cycle reduced investment compared to two separate systems

- ElectroMech’s experienced team and large manufacturing facility drastically reduced the procurement cycle time for the customer

- Solutions which offer highly reliable performance

- Assurance of prompt service

Solutions from ElectroMech

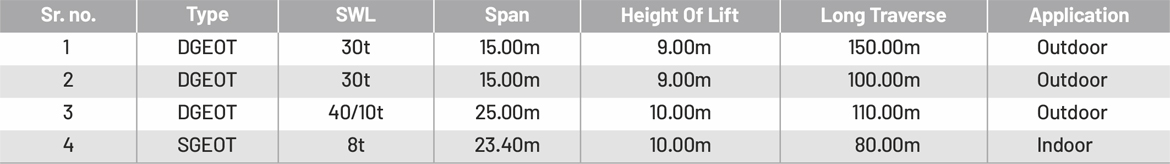

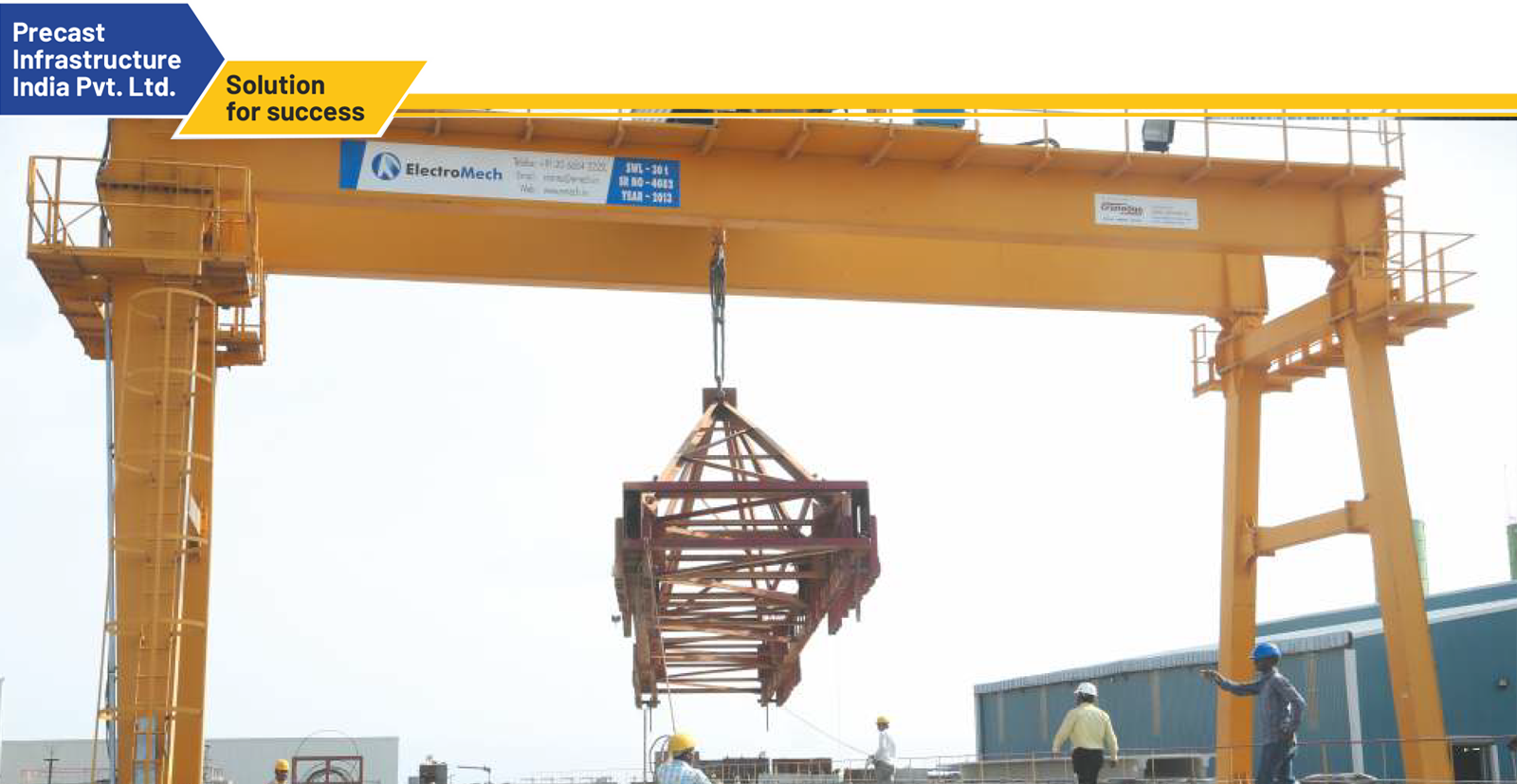

ElectroMech suggested three double girder gantry cranes to work in different bays in the outdoor casting yard, where large and heavy castings are manufactured. These cranes are fitted with Abus hoists which demonstrate peak performance in extreme working conditions and require minimal maintenance. One 8t single girder crane was recommended for the indoor application where smaller moulds and precast columns are to be handled.

Transporting and installing these cranes in a remote and hilly location, that too in a short time span, was also a big challenge. Team ElectroMech, with its large manufacturing plant and vast experience of working on various difficult sites across the world, was able to manufacture and install the cranes in just 12 weeks, which was well before the stipulated time.

Total number of cranes: 22

Challenges

- Cranes required to perform reliably in a dust-laden environment

- Very short time period from project conceptualisation to commissioning at the site

- Unique lifting requirement at the site, which included precise handling of heavy precast segments with the help of a lifting beam

Solution

- Sturdy cranes using Abus hoists to ensure trouble-free performance

- Abus hoists ensured that the crane loads are kept minimum, which helped reduce the level of foundation grades

- Double hooks and parallel hoisting arrangement avoids duplication of handling

- Completion of lifting in once cycle

- Optimally designed cranes to fit into the given budget