Single Girder And Double Girder EOT Cranes For Safe Glass Handling

WE ARE YOUR SOLUTION

When it comes to handling precious, fragile and large loads, an ElectroMech crane is the perfect choice.

About Saint-Gobain Pvt. Ltd.

Saint-Gobain is a 350-year-old French multinational corporation founded in 1665 in Paris. Originally a mirror manufacturer, it now also produces a variety of construction and high-performance materials. Saint-Gobain’s Chennai facility now has two float glass lines with a total capacity of 1500 tonnes a day; mirror and lacquer lines of 50 million sq. ft.; and a Magnetron Coater of 60 million sq. ft. for the construction industry. Its World Glass Complex at Sriperumbudur, Chennai caters not only to the Indian subcontinent, but also to entire Africa, Middle East and ASEAN markets.

Requirements

In the year 2016, Saint-Gobain decided to expand its capacity by setting up its third float glass manufacturing plant, an advanced Magnetron Coater and glass solutions line. The new plant is now commissioned and equipped with various modern features.

While planning the new factory, Saint-Gobain involved ElectroMech to competently address their material handling requirements at two locations.

Magnetron Coater

A Magnetron Coater uses magnetron sputtering technology that deposits a thin, nanolayer under vacuum conditions. It is mainly used for depositing many types of materials on glass surfaces using specially formed magnetic fields. The process creates highly resistant stable coating, making the glass resilient to sunlight and temperature. For these types of glass coatings, more number of chambers and equipment are required and in turn, a bigger coater. This necessitated the use of overhead cranes for routine maintenance of various equipment used in the coater.

Glass Sheet Stacking

After coating, large glass sheets are stacked, packed properly and stored in separate yards. These coated glass sheets come in various thicknesses and sizes, the largest being 4m x 5m. The weight of such stacks is around 4t and they need to be handled carefully. Overhead cranes were considered as the most feasible option for this handling requirement.

Handling challenges

The requirement of Saint-Gobain was unique as the handling of large sheets of delicate glass was involved. Such applications necessitate a crane of reliable engineering ensuring high levels of safety. However, the major challenge was to design cranes with low headroom as the client was in the process of finalising the PEB design. For such a massive factory, using cranes with lower headroom could offer a great cost advantage. Lower headroom for cranes means reduction in the overall height of the factory building and huge saving in the overall PEB cost.

With this idea, Saint-Gobain approached several crane manufacturers including ElectroMech. Also, for handling large glass stacks in a safe manner, special fixtures were to be considered and additional safety features were essential. Handling several tons of glass production everyday means that cranes were expected to perform round the clock and hence, the reliability of cranes and after-sales support were also key factors while selecting a crane manufacturer.

Solution from ElectroMech

Knowing the requirement of Saint-Gobain, ElectroMech suggested using single girder cranes in the Magnetron Coater bay and double girder cranes for the glass stacking area.

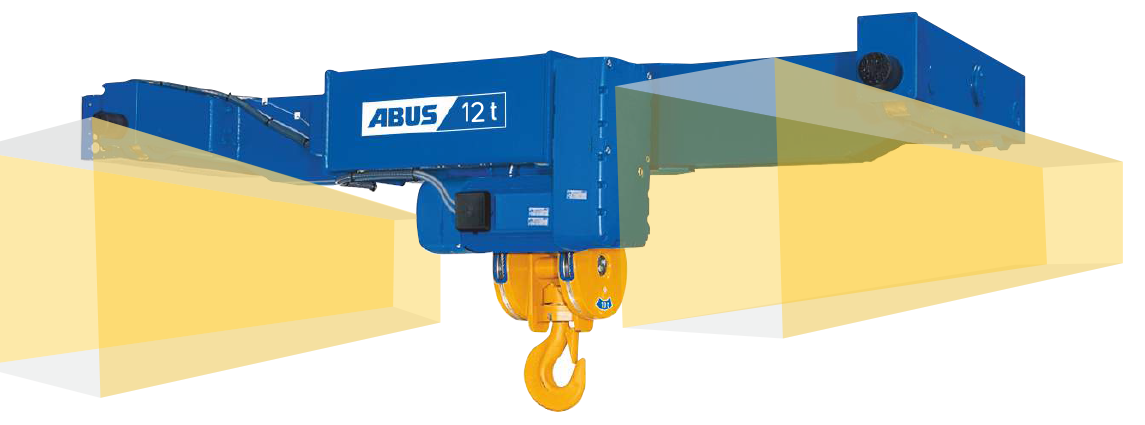

To address the challenge of headroom height, we suggested using Abus DA model hoists. The headroom provision in the design of the new factory building was merely 790mm, whereas cranes using Abus DA model hoists require only 760mm. This was a relief for Saint-Gobain as they could go ahead with the factory construction as per the original plan.

DA model hoist is a unique product from our partner Abus Crane Systems, Germany, and is specially designed for low headroom spaces. Its compact, sleek design requires very less space and lower headroom compared to almost all other hoists available in the market.

The complete solution from ElectroMech consisted of,

For Magnetron Coater Bay

| Type | SWL | Span | HOL | Nos. |

|---|---|---|---|---|

| Single Girder EOT Cranes | 6.3t | 21m | 6m | 2 |

Features

- Anti-collision device is provided since both the cranes are working in the same bay and on the same rail

- Use of DA model hoist has resulted in increased height of lift by 3m

For Glass Sheet Stacking Yards

| Yard | Type | SWL | Span | HOL | Nos. |

|---|---|---|---|---|---|

| 1 | Double Girder EOT Cranes | 9t | 24m | 7m | 2 |

| 2 | Double Girder EOT Crane | 12t | 23m | 7m | 1 |

Features

- Use of Abus DA model hoist has resulted in increased height of lift by 3m

- Abus DA model hoists are designed to perform in severe conditions. They can be operated continuously for longer periods with frequent start-stops

- Highly reliable and safe DC Disc Brake

- Reliable double-action limit switch

How Saint-Gobain benefits from the ElectroMech solution

- Saint-Gobain was in a position to save significant expenditure by limiting the factory height. This was possible only because of Abus DA model hoists which require very less headroom compared to others.

- Increased HOL by 3m with the use of advanced technology Abus DA hoist

- Specially engineered fixtures to handle heavy and bulky loads in a safe manner

- Continuous operation as our well-engineered cranes are meant to perform 24x7

- Safe operation through several built-in features – a standard advantage with all ElectroMech cranes

- Assured, reliable after-sales service through the expert team of Cranedge (Cranedge is a service subsidiary of ElectroMech)

Challenges

- Cranes with low headroom were essential

- Special fixtures were to be considered for careful handling of large glass stacks

- Additional safety features were necessary considering delicate load

- Cranes were expected to perform round the clock

Solution

- Abus DA model hoist was recommended which requires only 760mm headroom

- Specially designed fixtures were supplied

- Anti-collision device and DC disc brakes provide additional safety

- Assured, reliable after-sales service from Cranedge