WE ARE YOUR SOLUTION

An innovative stacker crane solution for storing steel coils. Saves nearly 50% floorspace and drastically cuts down retrieval time.

An innovative stacker crane solution for storing steel coils. Saves nearly 50% floorspace and drastically cuts down retrieval time.

Jindal Stainless Group is India’s largest manufacturer of stainless steel in certain grades and ranks amongst the top ten stainless steel conglomerates in the world. The company is known for adopting the latest technology and the best safety practices in the stainless steel industry.

The Hisar plant was established in 1975. It is India’s first stainless steel manufacturing unit and today, it is a fully integrated stainless steel plant with a capacity of 800,000 TPA. The Speciality Product Division caters to the high-end precision and speciality stainless steel requirements which include slabs and blooms, hot rolled coils, strips, plates, coin blanks, precision strips and coils.

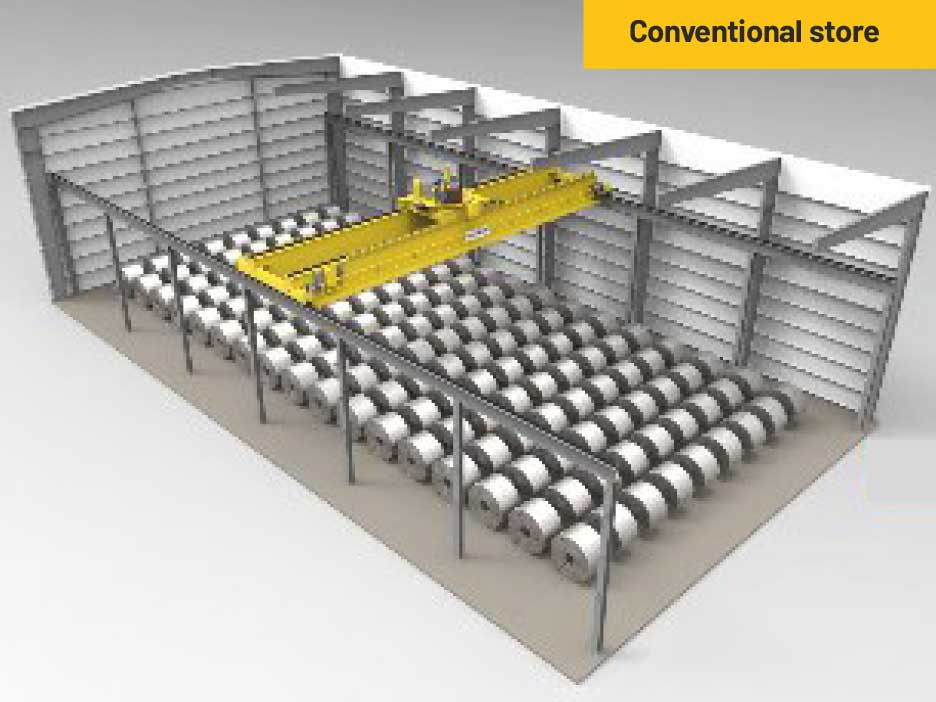

At the Hisar plant, after production, steel coils are stored in a separate warehouse before despatching them to the respective customer. Considering the daily production, almost 600 coils have to be stored routinely in this warehouse. Each coil has a different dimension and weight as it is manufactured according to the requirements of customers. The coils are relatively small in size and weigh less than 3t. The internal diameter of the coils ranges between 500mm and 600mm, and the outer diameter and width vary from coil to coil. Conventionally, coils are either kept on the floor or stored in two-tier racks using a forklift. Accessing individual coils is time-consuming and laborious in addition to the requirement of large floorspace.

JSL-Hisar was looking for a suitable system by which it could make use of vertical space and optimise the floorspace utilisation in addition to enhancing the store efficiency.

At ElectroMech, we have a separate team that tackles such unique storage and retrieval requirements and provides Integrated Store Management Solutions (ISMS). After knowing about the requirement at JSL-Hisar, the team was confident that our Stacker Crane with a few additional customised features could best address the challenge.

A Stacker Crane is an ingeniously designed double girder crane that combines the stability of an overhead crane and the flexibility of a forklift/lift truck. Its unique features include:

ElectroMech has supplied several stacker cranes to a wide range of industries such as pharmaceutical, foundry, engineering and electrical where generally material is palletised. However, the requirement at JSL-Hisar was unique as the coils are not palletised and the load of each coil was 3t.

The ElectroMech team conducted a thorough audit of the requirement including the material flow pattern. Based on the findings, a complete store layout and a customised stacker crane solution was developed by our team.

| SWL | Span | HOL |

|---|---|---|

| 3t | 17.6m | 4.1m |

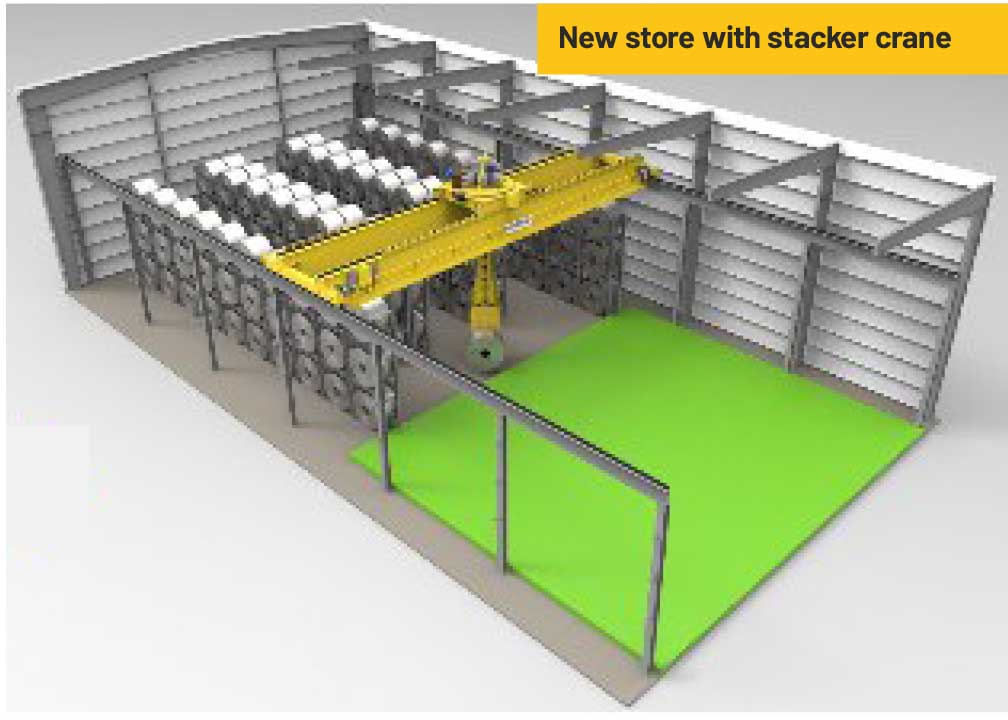

Once the idea of using a stacker crane was finalised, we recommended a suitable 4-tier (G+3) racking system. This made use of nearly the complete available height (5.5m) and nearly halved the floorspace requirement.

A stacker crane moves on the rails supported by the building structure during the long traverse, whereas for cross traverse, it is supported by crane girders. A rotating mechanism and a mast are fitted to the crab allowing rotation of mast and in turn the fork, through 360°. For stacking and retrieving coils, the stacker crane reaches the coil and the fork gets inserted which is then moved to the desired location. With the 360° rotation of the fork, it is possible to approach the coil from all possible directions, requiring very small aisle space.

The entire system is provided with a semi-automatic controller to ensure easy and quick access to stored coils.

A novel solution from ElectroMech in the form of the Stacker Crane has helped JSL-Hisar to significantly cut down operational costs and increase productivity besides ensuring safe handling.

Floorspace saving – With the new Stacker Crane system, JSL-Hisar is able to save nearly 50% floorspace as compared to earlier. With the 4-tier shelving by using available height upto 5.5m, storage capacity is almost doubled, leading to lesser floorspace requirement. Additionally, a stacker crane requires lesser aisle space, resulting in further floorspace saving.

Increased productivity – With the stacker crane, any coil can be accessed easily and quickly unlike when the coils are stored on the floor. Retrieval time of any coil, even from the farthest end of the aisle, is just three minutes. This saves substantial time and increases the overall stores efficiency and productivity.

Higher safety – The specially designed fork ensures a firm grip on the coil while lifting and handling. This avoids the possibility of accidental falling or damage to the coil or operator.

Operator comfort – The stacker crane can be operated from a distance using remote control, and hence, the operator does not have to travel every time with the equipment for storing or retrieving coils.

Disclaimer

© Copyright 2020 | All the names and logos used here are the registered trademarks of respective companies. For private circulation only. Certain data mentioned here is based on assumptions and theoretical calculations, hence may not be accurate in practice and can’t be considered as a claim by the company.